In engineering and manufacturing, joining materials is a fundamental process. The two primary methods for this are mechanical fasteners and adhesives. Each method has its own advantages and limitations, making it essential to understand their differences and applications to choose the right solution for a specific project. This article explores the characteristics, benefits, drawbacks, and applications of mechanical fasteners and adhesives, providing a comprehensive comparison to help in making informed decisions.

Mechanical Fasteners

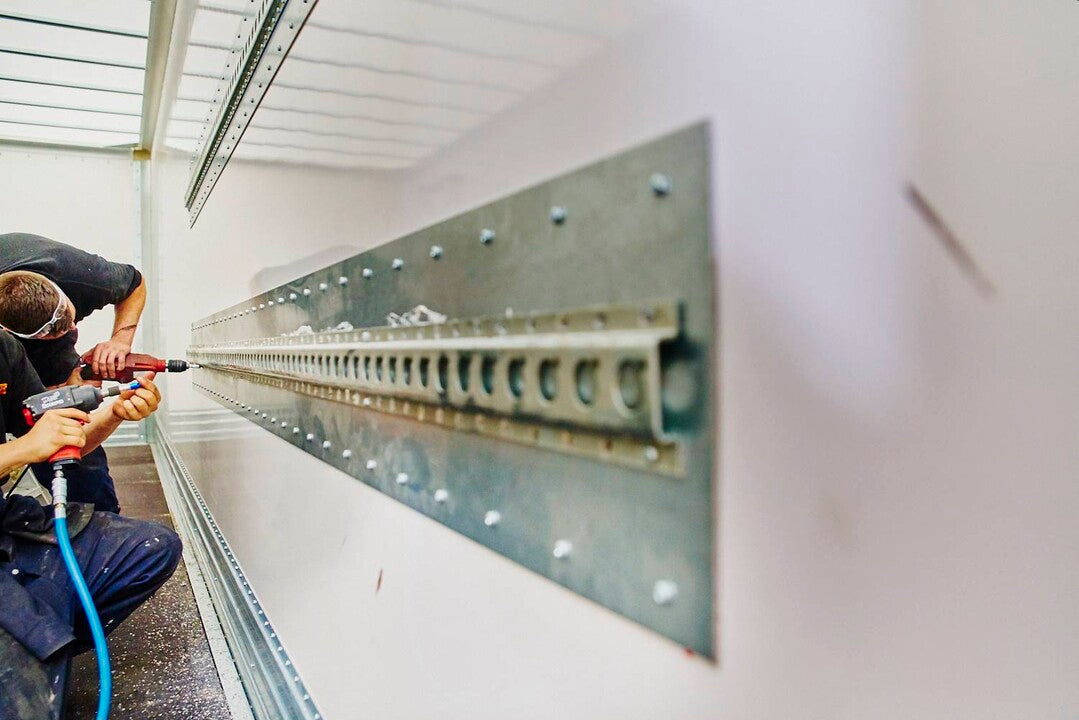

Mechanical fasteners include screws, bolts, nuts, rivets, and clips. These components physically hold parts together, typically by applying clamping force and creating friction between the joined parts.

Advantages of Mechanical Fasteners:

Strength and Durability: Mechanical fasteners provide high strength and are capable of withstanding significant loads and stress. They are reliable in both static and dynamic applications.

Ease of Assembly and Disassembly: Fasteners allow for easy assembly and disassembly, making them ideal for applications that require maintenance, repairs, or adjustments.

Versatility: Mechanical fasteners can join a wide variety of materials, including metals, plastics, and composites. They are suitable for both temporary and permanent joints.

No Curing Time: Unlike adhesives, mechanical fasteners do not require curing time. Once fastened, the joint is immediately ready for use.

Quality Control: Fasteners can be inspected visually, ensuring proper installation and reliability. Torque specifications can also be applied to ensure consistent clamping force.

Disadvantages of Mechanical Fasteners:

Weight: Mechanical fasteners add weight to assemblies, which can be a disadvantage in applications where weight reduction is critical, such as in aerospace and automotive industries.

Stress Concentration: Holes drilled for fasteners can create stress concentrations, potentially leading to material weakening and failure.

Corrosion: Fasteners made of different materials than the components they join can lead to galvanic corrosion, compromising the joint over time.

Aesthetics: Visible fasteners can detract from the appearance of a product, making them less suitable for applications where aesthetics are important.

Adhesives

Adhesives are substances used to bond surfaces together by forming a chemical bond. They come in various forms, including liquids, pastes, tapes, and films, and are classified based on their chemical composition and curing mechanisms.

Advantages of Adhesives:

Weight Reduction: Adhesives contribute minimal weight to assemblies, making them ideal for applications where weight savings are crucial.

Even Stress Distribution: Adhesives distribute loads evenly across bonded surfaces, reducing the risk of stress concentrations and improving the overall strength of the joint.

Aesthetics: Adhesive joints are typically invisible, providing a cleaner and more aesthetically pleasing appearance.

Sealing Properties: Many adhesives also function as sealants, providing protection against moisture, dust, and other environmental factors.

Bonding Dissimilar Materials: Adhesives can bond a wide range of dissimilar materials, including metals, plastics, glass, and composites, without causing galvanic corrosion.

Disadvantages of Adhesives:

Curing Time: Adhesives often require time to cure and reach their full strength, which can slow down assembly processes.

Temperature Sensitivity: Adhesives can lose strength at high temperatures or become brittle at low temperatures, limiting their use in extreme environments.

Surface Preparation: Proper surface preparation is critical for achieving strong adhesive bonds. Contaminants, oils, or oxidation on surfaces can weaken the bond.

Difficult Disassembly: Adhesive joints are generally permanent, making disassembly challenging without damaging the components.

Loctite HY 4090

One of the most advanced adhesive solutions on the market is Loctite HY 4090, a hybrid adhesive that combines the best properties of structural adhesives and instant adhesives. Loctite HY 4090 offers numerous benefits that make it an excellent choice for demanding bonding applications.

Exceptional Bonding Strength: Loctite HY 4090 delivers high bonding strength, making it suitable for structural applications where reliability is paramount. It can bond a wide range of materials, including metals, plastics, and composites.

Fast Curing Time: This adhesive features a rapid curing process, allowing for quicker assembly times compared to traditional adhesives. It reaches handling strength in minutes, enhancing production efficiency.

Versatility: Loctite HY 4090 is designed to perform in various environmental conditions. It maintains its strength and integrity under high temperatures, moisture, and chemicals, making it ideal for both indoor and outdoor applications.

Durability: The hybrid formulation of Loctite HY 4090 provides excellent impact resistance and durability. It can withstand vibrations and dynamic loads, ensuring long-term performance in demanding applications.

Ease of Use: Loctite HY 4090 is easy to apply, with a two-part system that mixes quickly and applies smoothly. It does not require special equipment or complex processes, making it accessible for various industrial settings.

Innovative Technology: As a hybrid adhesive, Loctite HY 4090 combines the best features of different adhesive technologies. It offers the quick set time of instant adhesives and the strong bonding capabilities of structural adhesives, providing a unique solution for challenging bonding tasks.

Conclusion

The choice between mechanical fasteners and adhesives depends on the specific requirements of the application. Mechanical fasteners are ideal for high-strength, easily maintainable, and versatile joints but may add weight and stress concentrations. Adhesives, particularly Loctite HY 4090, offer lightweight, aesthetically pleasing, and even stress-distributing bonds but require careful surface preparation and may have limited temperature resistance.

Understanding the advantages and limitations of each method helps engineers and manufacturers make informed decisions, ensuring the reliability and efficiency of their products. By selecting the appropriate joining method, industries can optimize their designs for performance, durability, and cost-effectiveness. Loctite HY 4090, with its superior performance and versatility, presents a robust solution for modern bonding challenges, offering a compelling alternative to traditional mechanical fasteners.

Leave a comment

All comments are moderated before being published.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.